Share:

Animal feed mixer machine price,ribbon type mixing machine

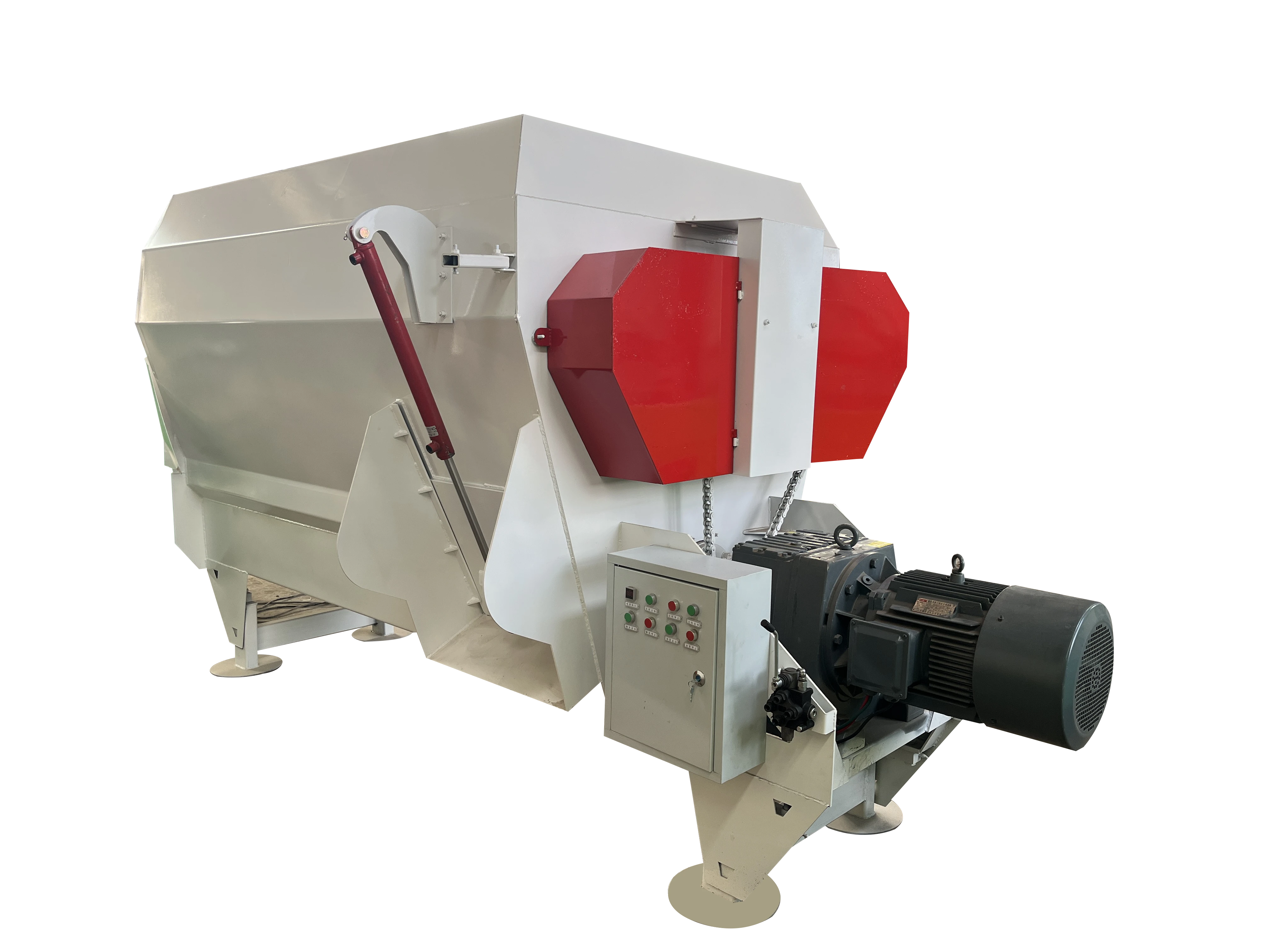

This horizontal ribbon feed mixer machine is suitable for mixing materials in various industries, such as powder, granular, flake, miscellaneous and viscous materials in feed, food, chemical, pesticide and other industries. It has a large effective volume and can add a variety of liquids, such as water and molasses, Grease, etc.

We recommend that customers must pay attention to a few points when choosing an animal feed mixer. 1. Material and layout of spiral belt or paddle; 2. Thickness of feed mixer body; 3. Motor, bearing, reducer; 4. Transmission mode is chain, belt, or direct connection. Only by more comparing can see high-quality products.

Product Details

Animal feed mixer machine is widely used for homogeneous mixing of powders and dry granules,such as concentrates or premixes.Feed mixing is playing a vital role in feed production line in order to ensure the quality and effect of compound feed. Feed mixing is to assure that an animal receives all of its formulated nutrient allowances every day. High efficient mixer machine ensures optimum feed mixing, easier distribution and many other benefits.

Therefore,the quality and performance of mixing machine directly influences survival and development of feed mills. Stable-performance feed mixer machine not only helps factory to keep making profits but also reduce large sum of money for maintenance and repairing. Our ranges of ribbon mixing machine are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending.This horizontal mixer put in a horizontal position, high mixing efficient, unloading quickly,good quality, less maintenance adapt to the wide range. So far it is the most commonly mixer in feed production plant.Available in capacities of 500 Kg, 1000 Kg, 1500 Kg and 2000 Kg.

Features of Animal Feed Mixer Machine

● Wide application: The ribbon mixing machine is widely used for feed, food additives, silicone rubber, pigment, printing ink,binder, paraffin, resin, etc.

● Stable structure:The horizontal mixer uses motor with gearing function obtained through chain drive,it’s robust, easy to use and requires little maintenance.

●Good performance:These are suitable for fine mixing (up to 99.5%) of medium to coarse dry materials of low moisture content (>13%),it is very efficient even with the presence of fats and molasses

● Large loading coefficient:Automatic feeder machine, small floor space, suitable for plant with large capacity.

●Unique design :The overall design is focused on being as clean and easy to maintain as possible.The electric wiring and other installations are integrated into the construction, making it easy to clean and maintain.The ladder is built into the end of the mixer for easy access, .

●Zeno Pellet Machine provide horizontal ribbon mixer for mix poultry and livestock feed mixing, as well as fish feed.Our feed mixing machine can mix the raw materials evenly.

Work Principle of Feed Mixer Machine

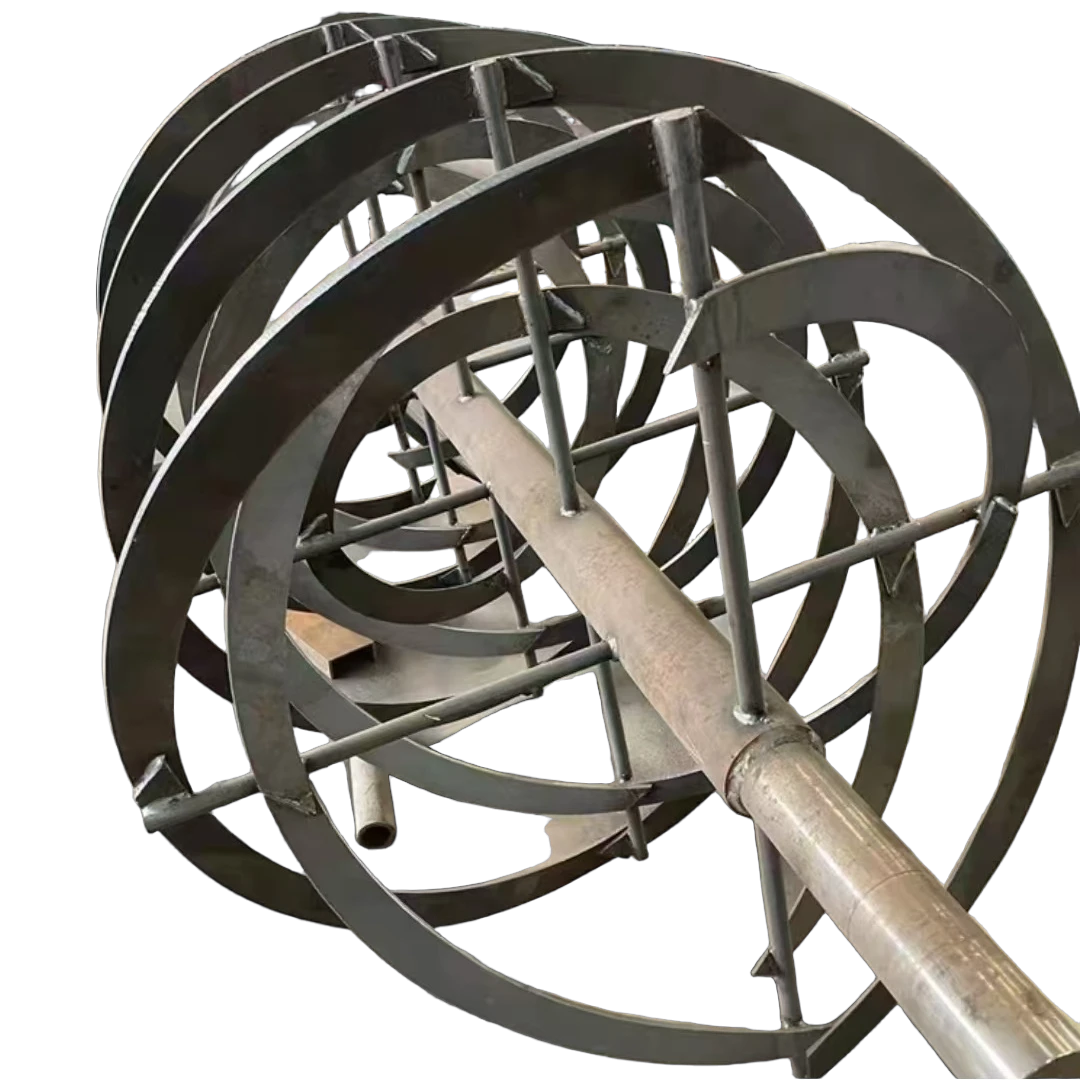

Turn on the machine motor,the speed reducer of the mixer drives the agitating shaft, the spiral ribbon on the shaft makes the materials turning up and down.The outer spiral presses the material from both ends to the middle,while the inner spiral pushes the material from middle to both ends, which helps discharging material,meanwhile lifting materials up along the inner wall of the mixer, it’s forming a circulation of materials inside the feed mixer machine machine to reach an even mixing effect evenly.

Technical Parameters

| Model | Power (kw) | Capacity (kg/h) | Size (mm) |

| ZNMJ150 | 3 | 150kg/batch 500~600kg/h | 1550*850*1450 |

| ZNMJ300 | 4 | 300kg/batch 700~800kg/h | 2200*770*1530 |

| ZNMJ500 | 5.5 | 500kg/batch 1000~1500kg/h | 2600*800*1700 |

| ZNMJ1000 | 7.5 | 1000kg/batch 2000~3000kg/h | 2700*1150*1750 |

| ZNMJ2000 | 15 | 2000kg/batch 4000~5000kg/h | 2800*2800*2000 |